Elastomeric connectors benefits:

- Solder-free connections.

- Zero Insertion Force.

- High-Density Contacts.

- Mixed Signal-Power Contacts.

- Low and Stable Resistance.

- Superior Performance Under Harsh Environmental Condition (Shocks, Vibration, Temperature etc.)

Click here for information about the process of assembling an LCD monitor on a PCB with LCD connector.

Elastomeric connector common applications

Our Elastomeric connectors are used in various applications:

- Board to Board Connections.

- Custom test fixtures - Customized Electrical Test Components.

- Matrix Connectors - BGA Surface Mounting Technology.

- Electroluminescent Display.

- Medical Devices – Health Care / Consumer / Hearing Aids.

- Military, Avionics & Aerospace Electrical Applications.

- Flat Panel Display Connections. PCB Connections.

- Mezzanine & Parallel Board Connections.

- Miniature connectors - Electronic Connections.

- Chip-to-board connections.

- Memory cards.

- Solderless connections.

- Process / Environmental Controls / Remotes.

- Telecommunications / Data.

- Drop-in replacement for exciting connector.

- Connect and test platform to mms, RF/coax, arrays, PCBs, flex etc & Test Sockets.

- Displays – Flat Panel, LCD, LED, Plasma, Projection.

- Portable Device.

- Point of Sale – Credit Card / Bar Coding / Smart Card / Security.

- Automotive.

And more...

Main Apllications

| Apllication |

Segment |

| Component to Board Connections - CTB |

LCD |

| Socket |

| Other |

| Board to Board Connections - BTB |

Mezzanine |

| RF / High Speed |

| Other |

|

Flex to Board Connections - FTB

|

ZIFF |

| Testing |

Elastomeric connector projects - Existing & future

- Raytheon

- Elbit Systems

- IAI

- API Technologies

- Philips Healthcare

- Syneron-Candela

- Flextronics

- Sanmina

- Capgemini

- 3M

- Mul-T-Lock

- Apple

And many more...

Z-Axis Europe offers revolutionary elastomeric connectors made of tightly spaced parallel rows of conductive filaments embedded in a silicone core. Our connectors are available in a variety of geometries, enabling introduction in numerous new applications.

Why Silicone Rubber?

- Does not crack or become soft or brittle.

- Less compression set.

- Unaffected by aging.

- Generates no corrosive chemicals.

- Does not degrade with UV, radiation, oxygen, ozone or humidity exposure.

- Flexible to temperatures as low as -55oC.

- Constant dielectric properties over wide range of temperature and humidity extremes.

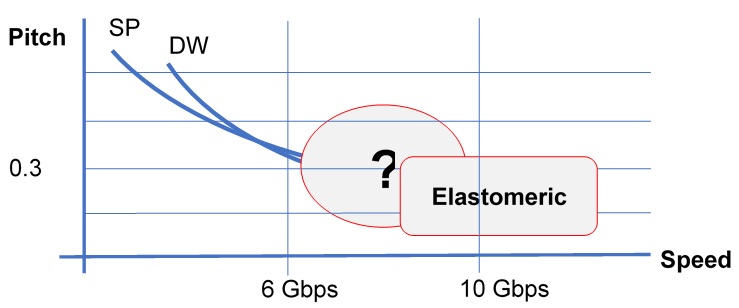

SP: Stamping, Plating, Assembly & Molding

DW: Drawn, Wire, Assembly & Molding